Brass Doors - from Bruton to Barbados

This journal post follows the story of our big brass doors, from the development of an idea and the testing of the design, to their completion in January in a cold Somerset barn and their installation in May, under a relentless Bajan sun.

As part of our Barbados beach house project one of the key elements was to create a new entrance. Referencing classical European architecture we proposed an all bronze door, set within a stone portal. The door is made up of interweaving and overlapping elements of bronze, forming 3m high panelled doors and a fish-scale tympanum.

For this task we were lucky to work with the talented and creative metalworker, Richard Drescher (RD Engineering). As a third-generation metalworker, the crafting, morphing and assembly of metal is in his blood, with an inherent understanding of its different abilities and limitations, its engineering possibilities as well as its poetic appeal. With his workshop close to our office, we were able to work hand-in-hand throughout the design and manufacturing stage, establishing a truly collaboration relationship between architect and maker.

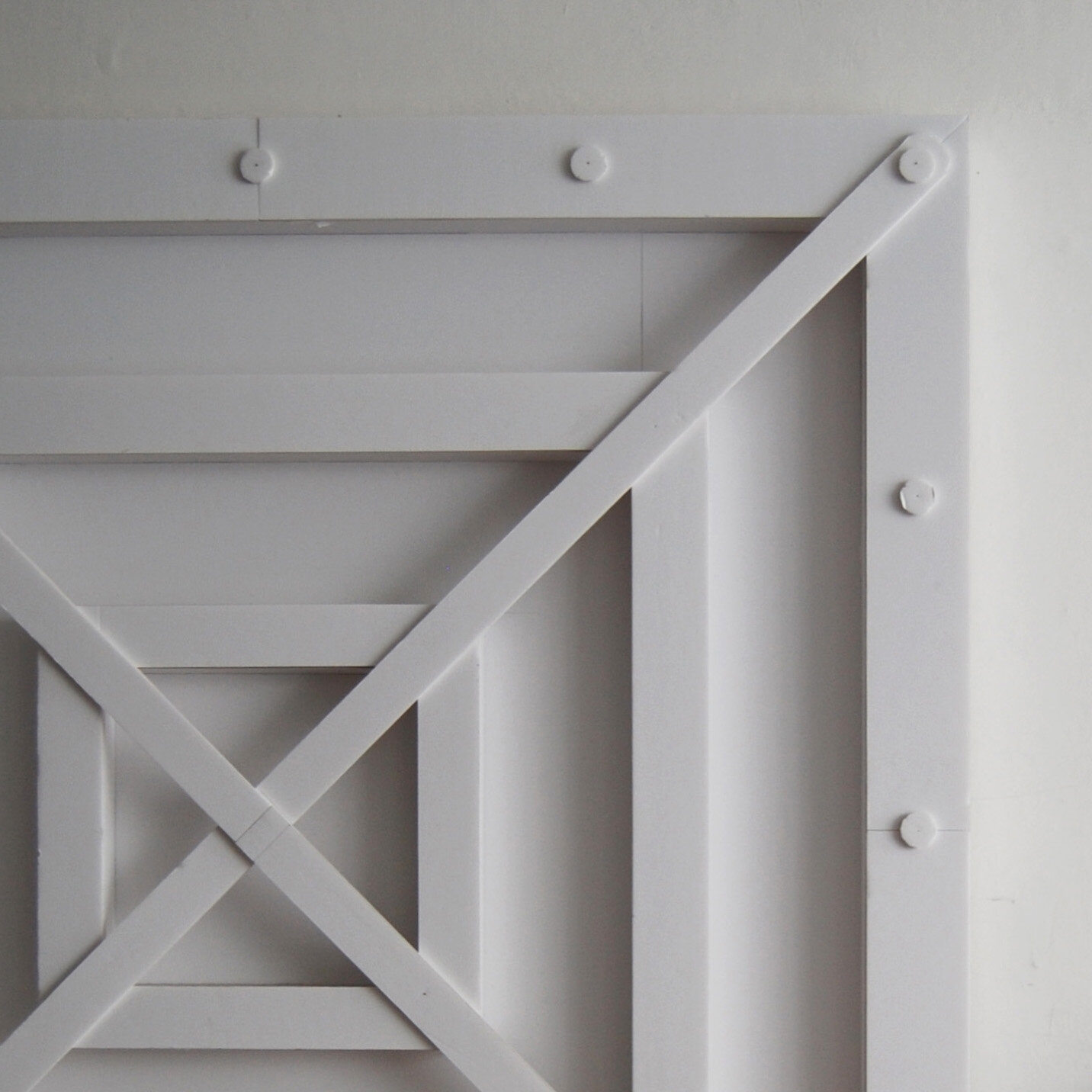

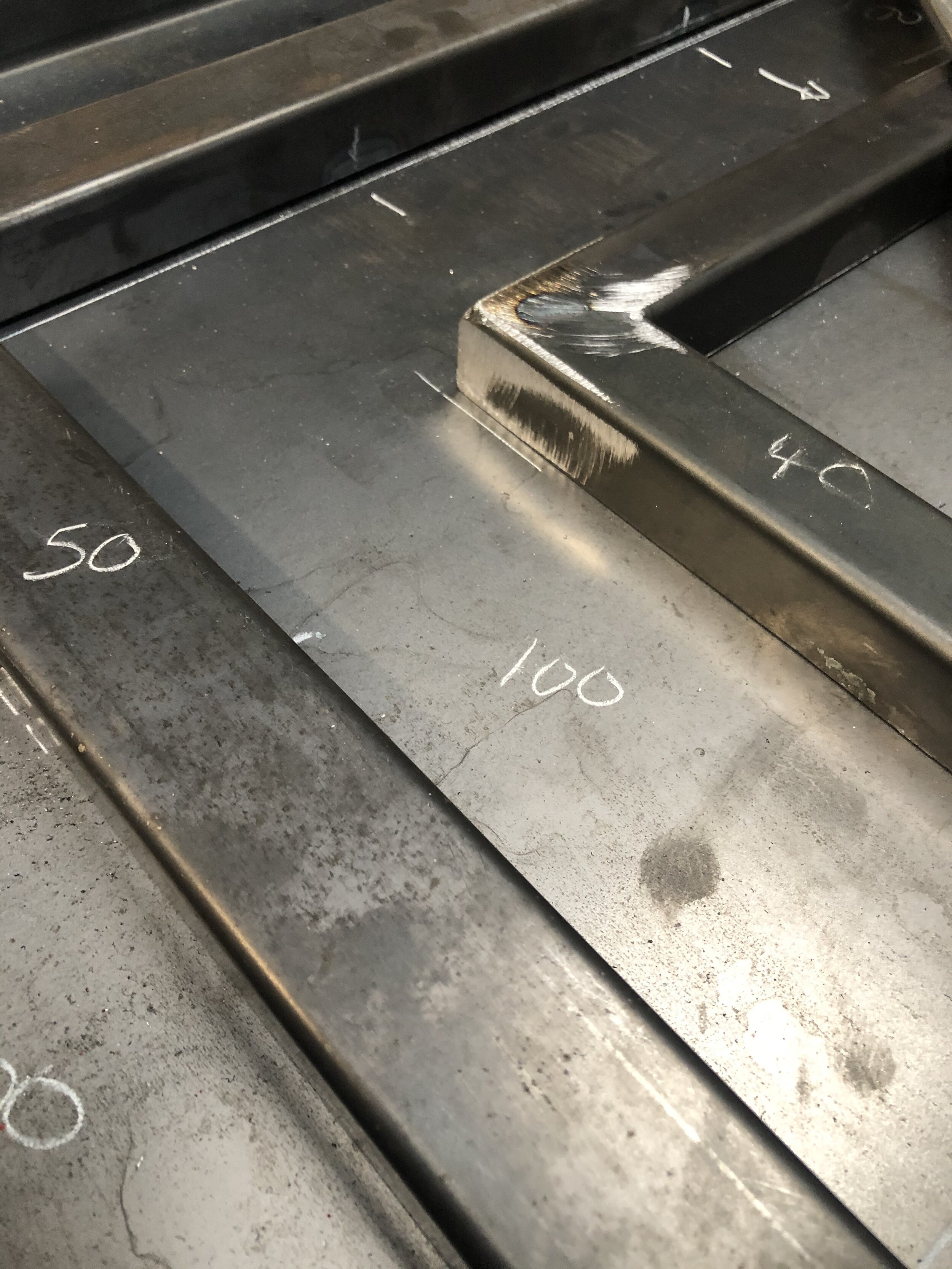

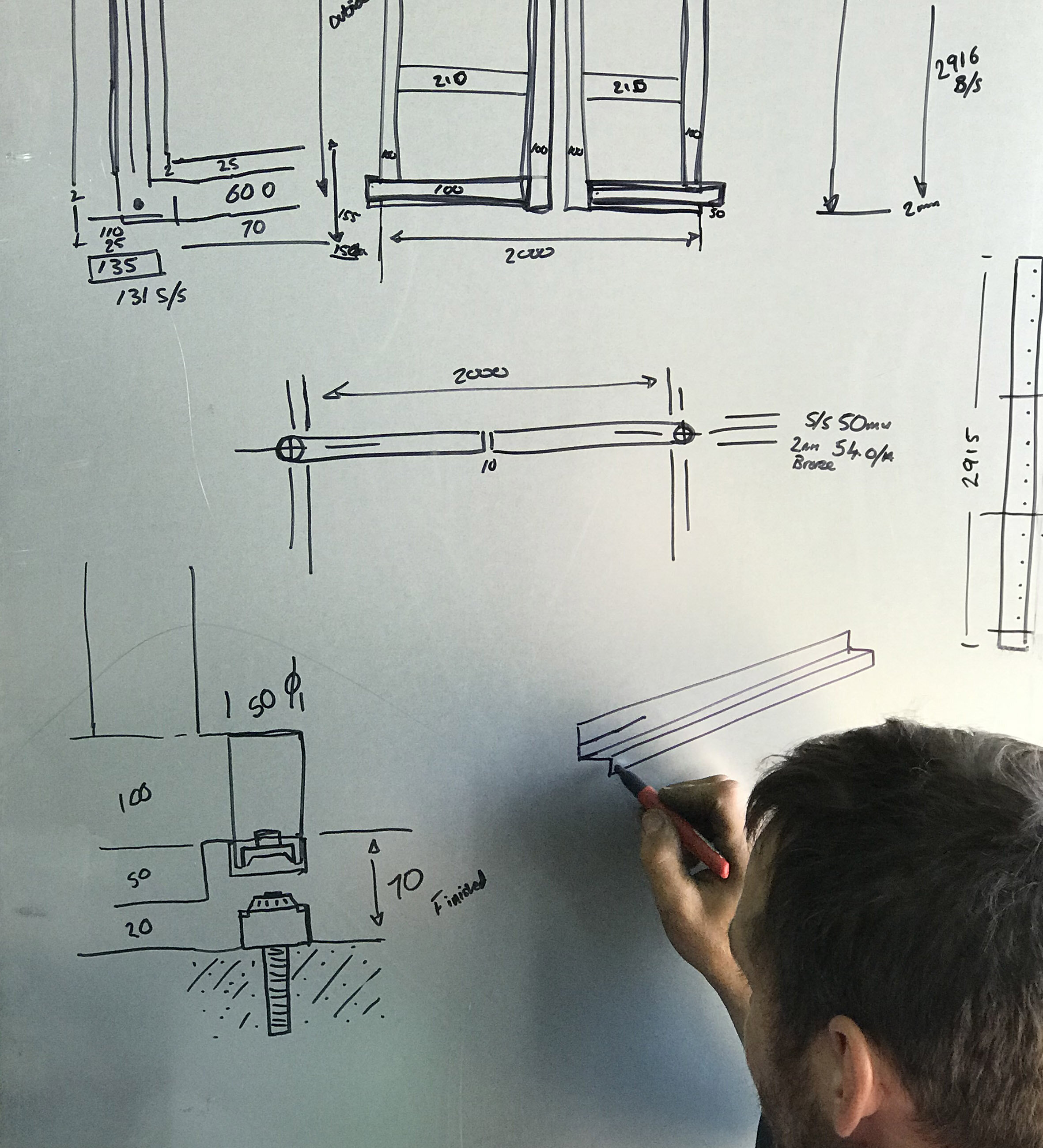

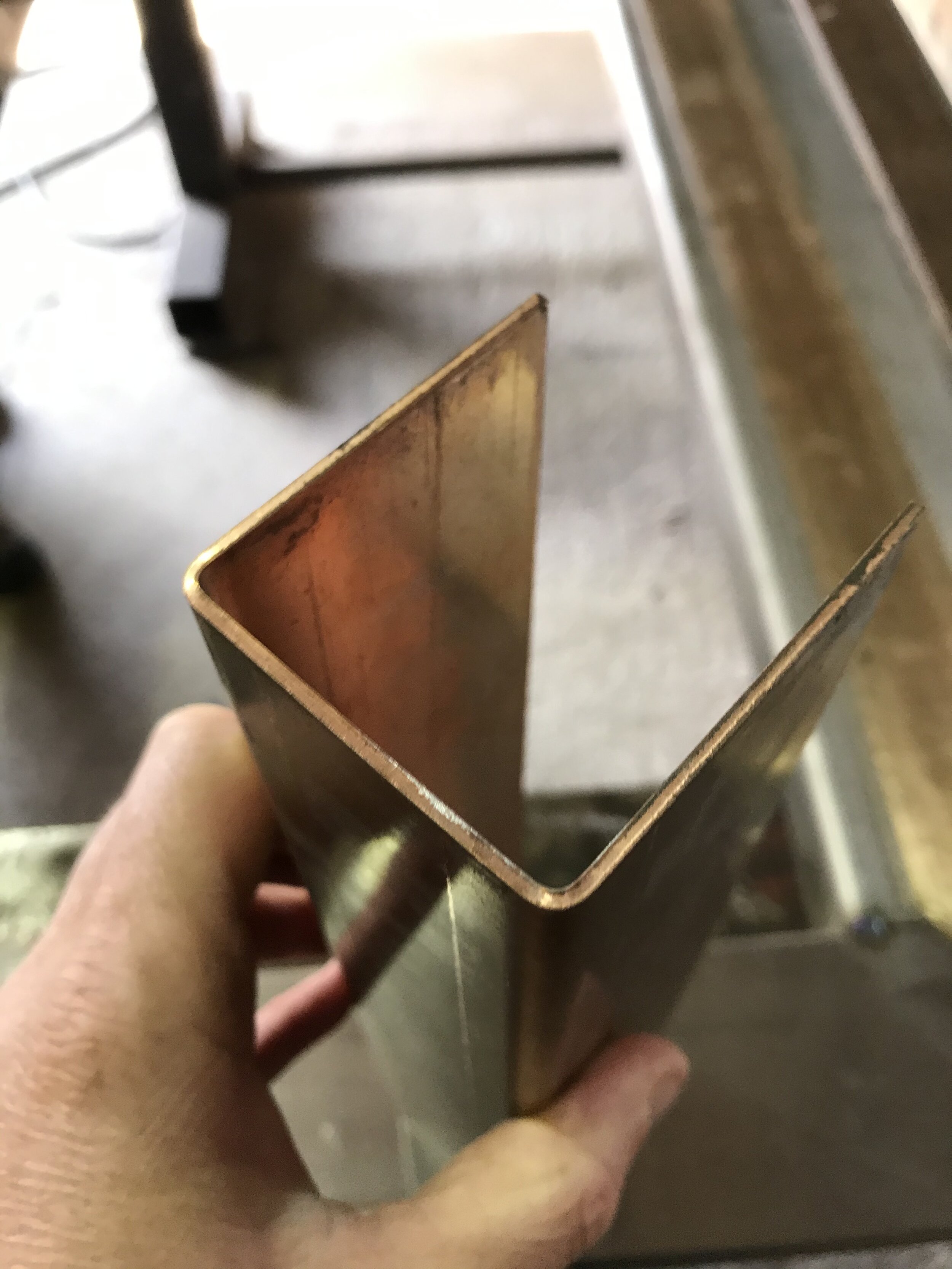

At the earliest stages we were able to share our ideas, exchange mock-ups and details, discuss techniques of bending, folding and joining, allowing the material to inform the design and articulate the detail. We started by making a simple 1:1 scale foam-board model, from which Rich created a steel mock-up, folding steel plates and testing joint locations.

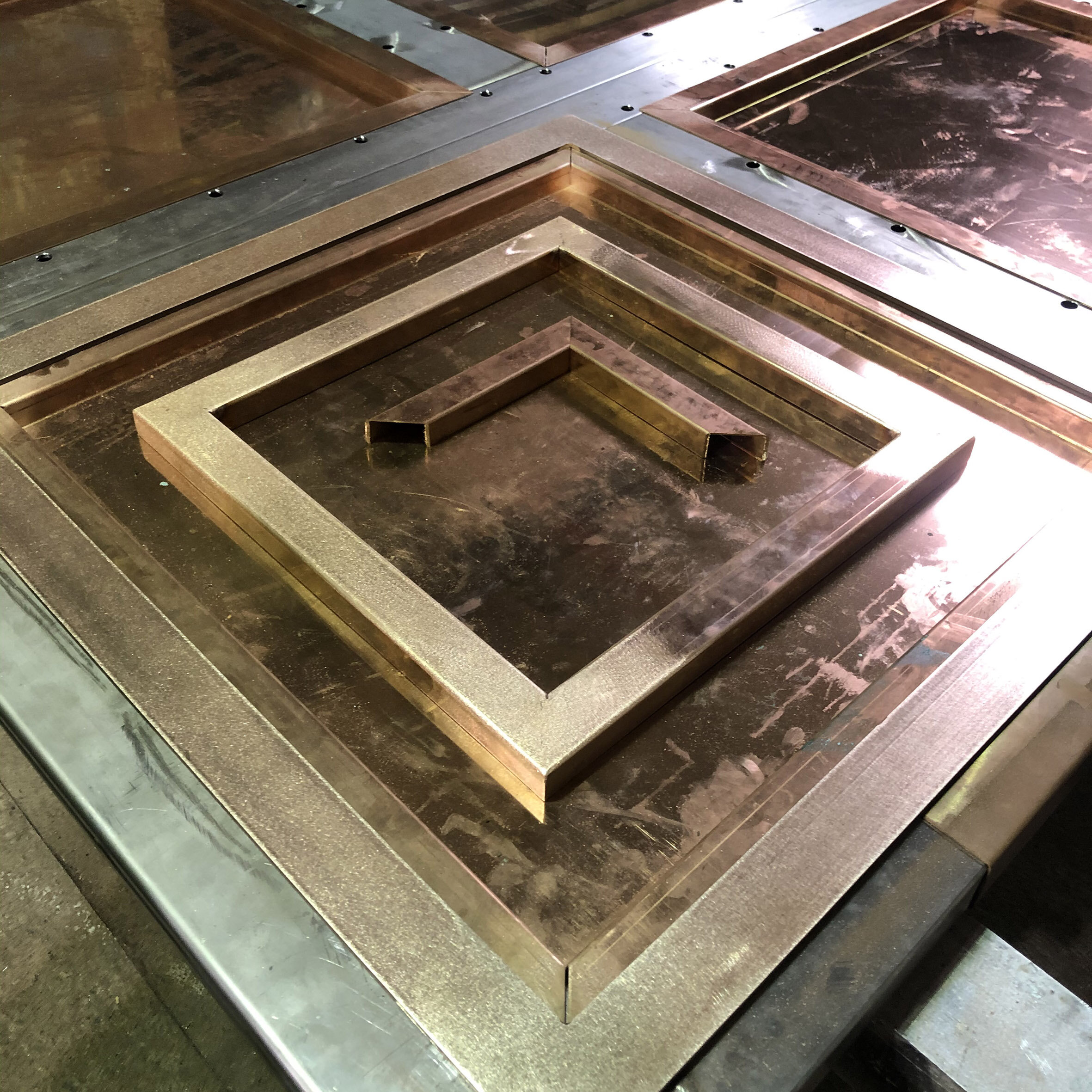

Once the principles of the metal folding and jointing was agreed, we re-sized the metal components, balancing overall proportion with structural integrity. Rich developed methods and sequences of fixing, and devised a structural steel frame around which the brass plates could be inset and folded.

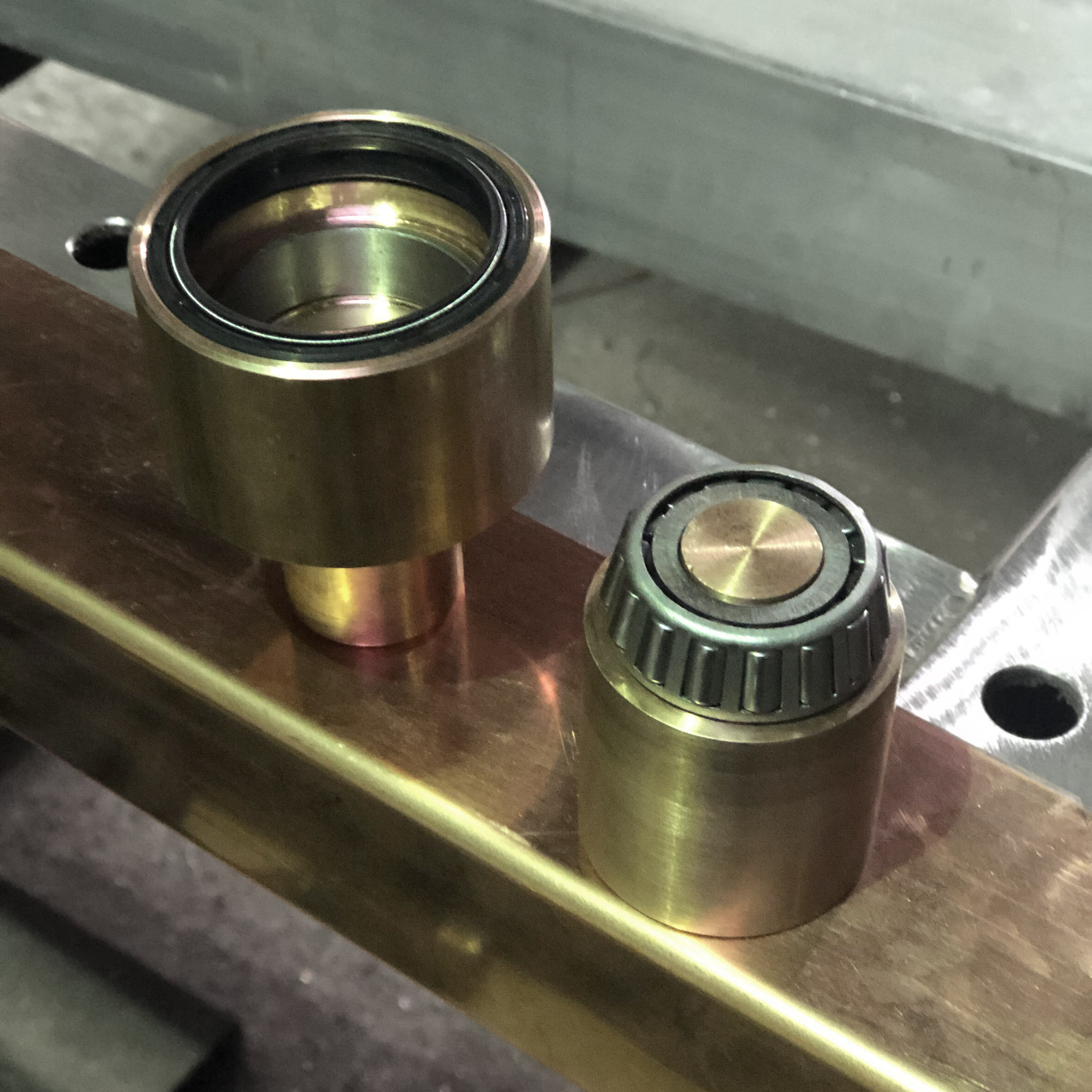

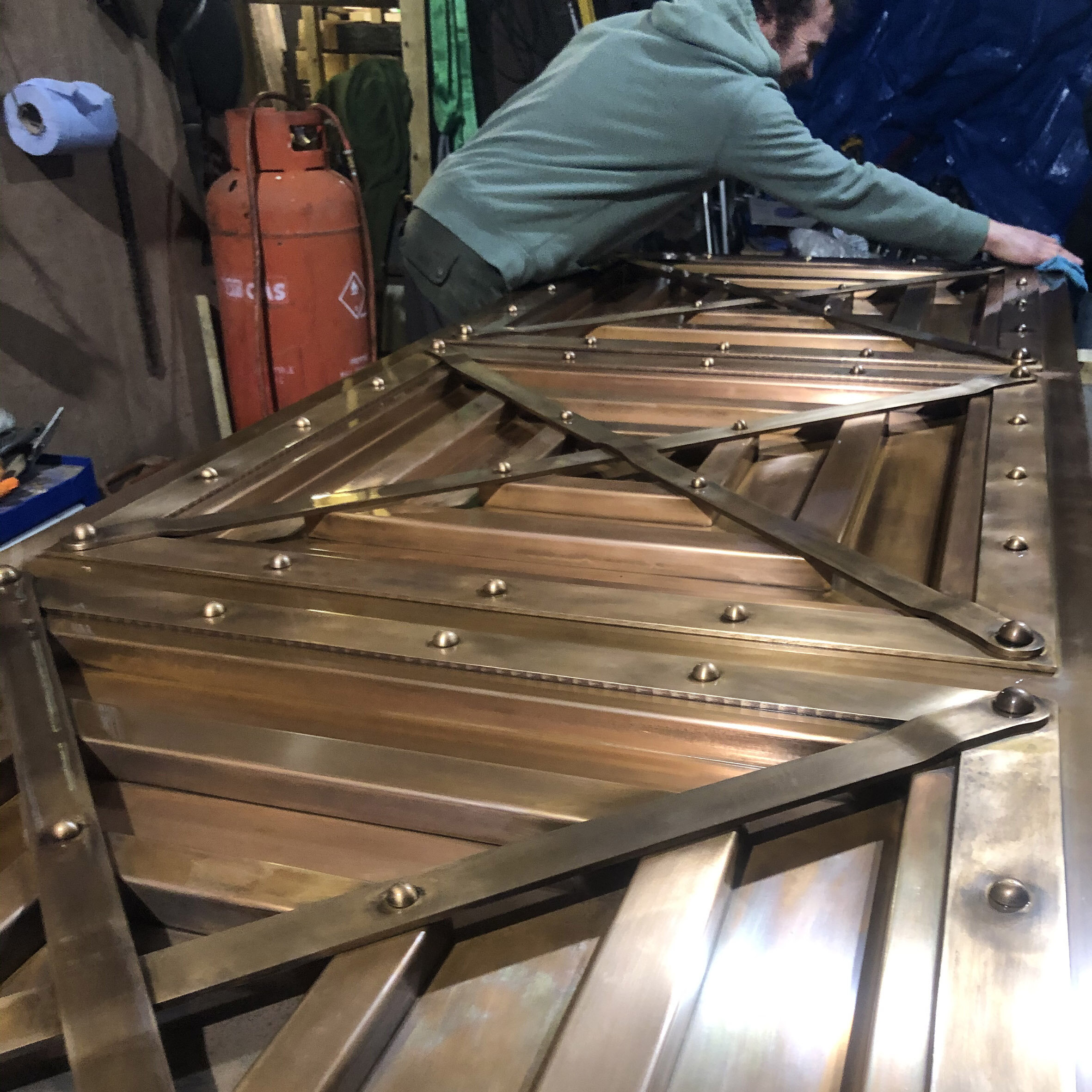

The brass plates are then fixed to the the steel frame with a serious of bespoke rivets, custom-made by Rich to three different sizes, according to the hierarchy of the panel. Rich calculated that the weight of each door leaf was approximately 1 tonne, therefore the pivot hinge (photographed on the upper right side) was of the utmost importance. Using a combination of proprietary and custom-made pieces, the larger ‘sleeve’ element would be set into the floor and filled with grease to avoid any water entering the joint. The smaller item, is then fixed into the cylinder on the side of the door (see image on the lower left side), and pivots effortlessly within the sleeve.

As well as the hinges, other bronze ironmongery was designed in collaboration, including a handle, latch and internal deadbolt. A language of solid bronze bars and hoops was devised for handle and latch and a texture was introduced to the handle, to invite touch.

Upon completion of the assembly, the doors were then patinated by Rich, with the help of local artisans and metal specialists. A diluted solution of potassium sulphide was applied to the metal and lightly flame-heated to accelerate the patination process (this work took place during a week in early January therefore this helped to encourage the natural chemical process). The doors were then rubbed back with tinted wax.

In addition to the doors, the semi-circular over-panel was formed with a series of half circles, made from 8mm thick brass plate. These were spot welded and sanded together within a frame, prior to be being finished by hand.

The doors were packaged up in Somerset and air-freighted by the specialist hauliers Williams and Hill, arriving one week later in Barbados. Due to the third lockdown it was not possible for us to return to site until May 2021, when Rich installed them on site, with the help of the local team. Under the extreme conditions of the Barbadian sun, the bronze started to patinated further, with some localised streaking from when the doors had been in storage. It was decided to very lightly sand back the surface and then allow the patination to occur naturally, which we expect to be over a few weeks.

These detail photos show the door insitu, set within an all stone portal and focusing on some of the details described above.

For more information on this project refer to our Beach House project folder.